Table of Contents

Fire safety has become an essential aspect of modern industry and daily life. Whether in construction, automotive manufacturing, or personal protective equipment, the need to prevent or slow down the spread of fire is paramount. Fire retardant cloth, with its ability to resist ignition and slow down combustion, plays a vital role in protecting lives and property. This comprehensive guide will take you through the essentials of fire retardant cloth, from its definition to its applications, key components, and the latest trends in the field.

What is Fire Retardant Cloth?

Fire retardant cloth is a material that has been chemically treated or inherently designed to resist fire. Unlike ordinary fabrics, which can catch fire and burn quickly, fire retardant cloth is either difficult to ignite or designed to slow down the spread of flames, giving people more time to evacuate and reducing the damage caused by fire.

There is often confusion between fire retardant and fire-resistant materials, but the distinction is crucial. Fire-resistant materials are inherently resistant to fire, meaning they do not need any additional chemical treatment to provide protection. Fire retardant materials, on the other hand, have undergone a chemical treatment or coating to enhance their fire-resistant properties. Both serve to reduce fire risk, but the methods and degrees of resistance vary depending on the material.

Fiberglass

Fiberglass Fire Retardant Cloth

How Does Fire Retardant Cloth Work?

The fire retardant properties of fabrics are either built into the fibers or applied as a finish. In either case, the aim is to interrupt the combustion process. Fire retardant fabrics typically work in two ways:

- Slowing the Burning Process: By releasing chemical compounds when exposed to heat, fire retardant cloth can inhibit the chemical reactions that fuel the fire. These compounds can act as a barrier, forming a protective layer on the surface of the fabric to stop it from burning further.

- Reducing Flammability: Some fire retardant materials prevent the fabric from reaching its ignition temperature. By either lowering the heat release rate or forming a char layer, fire retardant fabrics help to delay or prevent ignition.

Types of Fire Retardant Cloth

There are several different types of fire retardant cloth, each tailored for specific applications and industries. These include:

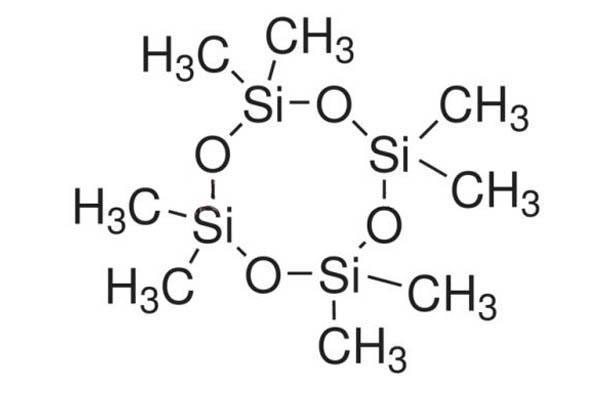

- Silicone-Coated Fabrics: One of the most popular fire retardant fabrics, silicone-coated materials are versatile and offer excellent heat and flame resistance. They are often used in industrial applications, such as ventilation ducts, gaskets, and protective gear.

- Fiberglass Fabrics: Fiberglass is inherently fire resistant, and when combined with fire retardant coatings, it becomes even more effective. Fiberglass fabrics are widely used in construction, especially for curtains and insulation materials.

- Aramid Fabrics: Aramid fibers, such as Kevlar and Nomex, are known for their incredible strength and heat resistance. These fabrics are commonly used in firefighting suits, aerospace applications, and automotive safety equipment due to their ability to withstand high temperatures.

- Neoprene-Coated Fabrics: Neoprene-coated fabrics are another versatile type of fire retardant material. Known for their durability and resistance to not only fire but also oil, chemicals, and weather conditions, they are commonly used in applications such as protective covers, hoses, and seals. Neoprene-coated fabrics offer excellent flexibility, making them suitable for dynamic environments where fire resistance is necessary, along with other protective features.

- Polyester and Cotton Blends: Polyester and cotton fabrics can also be treated with fire retardant chemicals to enhance their fire resistance. These materials are used in upholstery, curtains, and other interior furnishings that must meet fire safety regulations.

Each type of fire retardant fabric has specific advantages and drawbacks, making it essential to choose the right material for the intended application.

Key Components of Fire Retardant Cloth

Fire retardant cloth is made up of various fibers, coatings, and treatments that provide its unique protective properties. Understanding the composition of fire retardant fabrics helps in selecting the best material for specific needs. The key components include:

- Base Material (Fibers): The base fibers of the fabric play a significant role in determining its inherent fire resistance. For example, aramid fibers are naturally heat-resistant, while polyester and cotton fibers require additional chemical treatments to achieve similar properties.

- Fire Retardant Coatings: Many fabrics are treated with fire retardant chemicals to improve their resistance to flames. These coatings can include compounds such as phosphorus, chlorine, or bromine, which help interrupt the combustion process.

- Multi-Layer Construction: Fire retardant cloth often consists of multiple layers designed to offer varying degrees of protection. The outer layer may be made from a highly durable, flame-resistant material, while the inner layers provide insulation and comfort.

- Heat Reflective Elements: Some fire retardant fabrics include heat-reflective coatings that help protect against radiant heat. This is especially important in applications where workers are exposed to high temperatures, such as firefighting or industrial environments.

Each component works together to ensure that the fire retardant fabric can resist heat, flames, and the spread of fire for extended periods.

Applications of Fire Retardant Cloth

Fire retardant cloth is used across a wide variety of industries, each with unique fire safety requirements. Some of the most common applications include:

- Construction: Fire retardant cloth is frequently used in construction, especially for curtains, wall coverings, and insulation materials. These fabrics help slow the spread of fire in buildings, allowing for safer evacuation and reducing damage.

- Automotive and Aerospace: In both the automotive and aerospace industries, fire retardant fabrics are used for seat covers, insulation, and safety gear. The ability to withstand high temperatures is crucial in these environments, where fires can have catastrophic consequences.

- Firefighting Gear: Firefighters rely on fire retardant clothing to protect them from extreme heat and flames. Materials like Nomex and Kevlar are commonly used in firefighting suits due to their high-temperature resistance and durability.

- Industrial Applications: Fire retardant fabrics are also used in industrial settings for protective gear, gaskets, and flexible ducts. These materials help prevent fires in environments where high heat or sparks are common.

- Consumer Goods: Fire retardant fabrics are used in household items such as furniture upholstery, curtains, and carpets to reduce fire hazards in homes. Many countries have strict regulations regarding the use of fire retardant materials in consumer products.

The widespread use of fire retardant cloth underscores its importance in enhancing fire safety in both industrial and consumer applications.

Advantages of Using Fire Retardant Cloth

Using fire retardant cloth offers several advantages, especially in industries where fire safety is a top priority. Some of the key benefits include:

- Enhanced Safety: The primary advantage of fire retardant cloth is its ability to reduce the risk of fire. By slowing down or preventing the spread of flames, these materials help protect lives and property in fire-prone environments.

- Compliance with Fire Safety Regulations: Many industries are subject to strict fire safety regulations that require the use of fire retardant materials. Using fire retardant cloth ensures compliance with these standards, helping companies avoid legal issues and fines.

- Durability: Fire retardant fabrics are often more durable than untreated fabrics, making them suitable for use in harsh environments. They can withstand extreme temperatures without degrading, ensuring long-lasting performance.

- Cost-Effectiveness: While fire retardant fabrics may be more expensive upfront, their ability to prevent fire-related damage can save money in the long run. By reducing the risk of fires, companies can avoid costly repairs and downtime.

- Environmental Impact: Some modern fire retardant fabrics are designed with sustainability in mind. These materials are made from eco-friendly fibers or treated with non-toxic fire retardant chemicals, reducing their environmental footprint.

These advantages make fire retardant fabrics an essential component of fire safety strategies across various industries.

Choosing the Right Fire Retardant Cloth

When selecting fire retardant cloth for specific applications, several factors must be considered to ensure optimal performance. These include:

- Material Type: The base material of the fabric plays a significant role in determining its fire retardant properties. Aramid fibers, for example, offer superior heat resistance, while polyester and cotton blends may require additional treatments.

- Durability: Depending on the application, the durability of the fabric is essential. Fabrics used in industrial or outdoor environments need to withstand harsh conditions without losing their fire retardant properties.

- Weight: The weight of the fabric is another important factor to consider, especially for applications like protective clothing. Heavier fabrics may offer more protection, but they can also be less comfortable to wear.

- Regulatory Standards: It’s crucial to ensure that the fire retardant cloth meets the necessary fire safety regulations for the intended application. Different industries have specific standards that must be adhered to.

- Cost: While fire retardant fabrics may have a higher upfront cost, it’s important to weigh this against the potential cost savings from preventing fires and reducing damage.

By carefully considering these factors, companies can select the right fire retardant fabric for their specific needs, ensuring both safety and compliance.

Future Trends in Fire Retardant Cloth Technology

As technology advances, the fire retardant fabric industry continues to evolve. Some of the key trends shaping the future of fire retardant cloth include:

- Sustainable Fire Retardant Solutions: With growing concerns over environmental sustainability, there is increasing demand for eco-friendly fire retardant fabrics. Manufacturers are developing materials that are both fire-resistant and environmentally friendly, using natural fibers and non-toxic chemicals.

- Nanotechnology in Fire Retardant Fabrics: Nanotechnology is being explored as a way to improve the fire retardant properties of fabrics. By incorporating nanoscale additives into the fibers, manufacturers can create materials that offer enhanced protection against fire without sacrificing durability or comfort.

- Smart Fabrics: The development of smart textiles that can detect changes in temperature and react to heat is another exciting trend in fire retardant technology. These fabrics could offer real-time protection by changing their properties when exposed to fire, providing even greater safety for users.

- Improved Durability and Comfort: As fire retardant fabrics continue to improve, manufacturers are focusing on creating materials that are not only more effective but also more comfortable to wear. This is particularly important in industries like firefighting, where workers need to wear protective gear for long periods.

These innovations are likely to lead to more effective, sustainable, and comfortable fire retardant fabrics in the coming years, enhancing fire safety across industries.

Conclusion

Fire retardant cloth plays a critical role in protecting people and property from the dangers of fire. Whether used in construction, automotive manufacturing, or firefighting, these materials provide essential protection by slowing down or preventing the spread of flames. By understanding the different types of fire retardant fabrics, their key components, and how they work, companies can make informed decisions about which materials to use for their specific needs. As technology continues to advance, the future of fire retardant fabrics looks promising, with innovations in sustainability, nanotechnology, and smart textiles leading the way toward even greater fire safety.